Boutique bag production requires many processes

Cut-out for an opening, making holes for handles, threading the handle string through the holes. The time loss from changing dimensions when the order quantity is small while required to make many different shapes could result not only in the unit cost increase but also in the planning of the overall production.

At NLI Group, we have focused on every impediment though the manufacturing process and successfully eliminated them with reliable sheet feed. By automating the opening cut-out, hole opening, round handle string install drastically reduced the process time thus lowering the unit cost. We have two boutique bagging machine models.

Cut-out for an opening, making holes for handles, threading the handle string through the holes. The time loss from changing dimensions when the order quantity is small while required to make many different shapes could result not only in the unit cost increase but also in the planning of the overall production.

At NLI Group, we have focused on every impediment though the manufacturing process and successfully eliminated them with reliable sheet feed. By automating the opening cut-out, hole opening, round handle string install drastically reduced the process time thus lowering the unit cost. We have two boutique bagging machine models.

Roll Stand Fed Type

TS Series

TS Series regulates the motion of various parts using servo motors. These motors synchronize moves when speed and size changes are required greatly reducing the adjustment downtime through settings by an NC (numeric control) system.

TS Series regulates the motion of various parts using servo motors. These motors synchronize moves when speed and size changes are required greatly reducing the adjustment downtime through settings by an NC (numeric control) system.

The system is in a compact design eliminating any power transferring shafts making the workers stay at one location improving work efficiency and safety.

The NC (numeric control) has the following features while the machine is running.

• Setting the position of the sheet to be fed

• Web guide sensor positioning

• Handle patching glue positioning

• Handle positioning

• Handle pressing servo to attach with the glue

• Handle centering

Sheet Fed Type

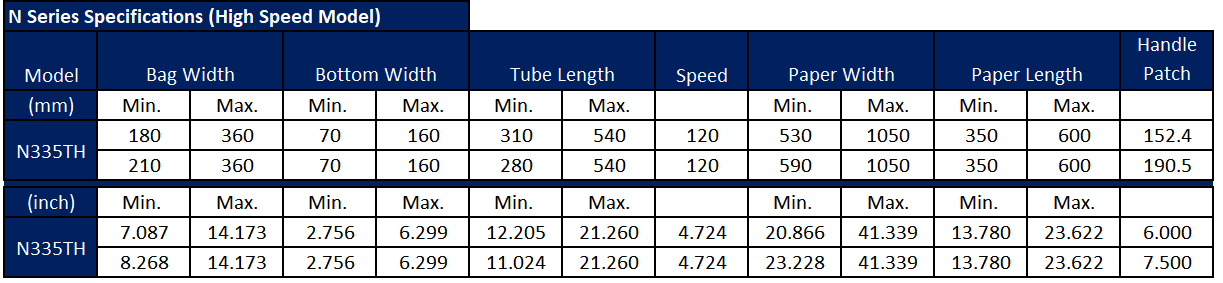

N300 Series: Servo controlled sheet feeder enables stable feed at any speed. It can adjust the dimensions on the fly suitable for variety of sizes at small quantity.

Automatically cuts opening, open holes for string handles, threading strings. It can attach flexible and long handle strings up to 30 centimeters (11.8 inches). Capacity 120 bags per minute.

Automatically cuts opening, open holes for string handles, threading strings. It can attach flexible and long handle strings up to 30 centimeters (11.8 inches). Capacity 120 bags per minute.

Sheet Feeding with Reel Unwinder Type

RS Series: The machine succeeded in cutting the sheet roll directly to reduce the bag thus greatly reducing material waste. Optimized for a large quantity of 10,000 bags per roll. Automatically cut out the bag opening, make holes for the handle strings, threads rounded handle strings. Capacity 100 ~ 120 bags per minute.